Book an Enapps demonstration!

Complete our enquiry form and we'll get back to you to arrange your free demonstration either on-site or in our London office

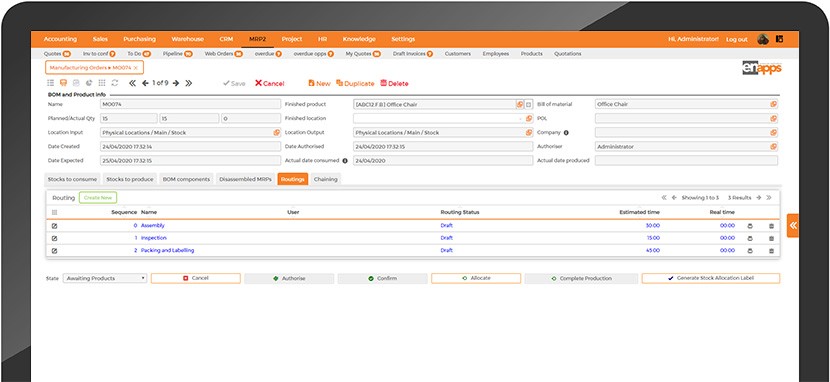

Enapps supply a flexible manufacturing ERP software module that natively supports most SME requirements. Routing and shop floor data capture via barcode scanning of jobs along with ‘make to order’ and ‘make to stock’ functionality are all supported as standard. The manufacturing module can also be configured to work with the project’s module supporting ‘project manufacturing’ which is used for manufacturing a bespoke product that has complex routings and where each Manufacturing Order is part of a larger project.

The Enapps MRP functionality allows a business to quickly manage Sales & Stock demand. It does this by fully utilising the Bill of Materials (BOMs) whilst considering the predefined stock settings for Min/Max stock holdings, MOQ’s, Supplier lead times along with any other parameters which are set by the operator. The ERP system will then suggest all of the Manufacturing Orders and Purchase Orders required to satisfy that particular demand.

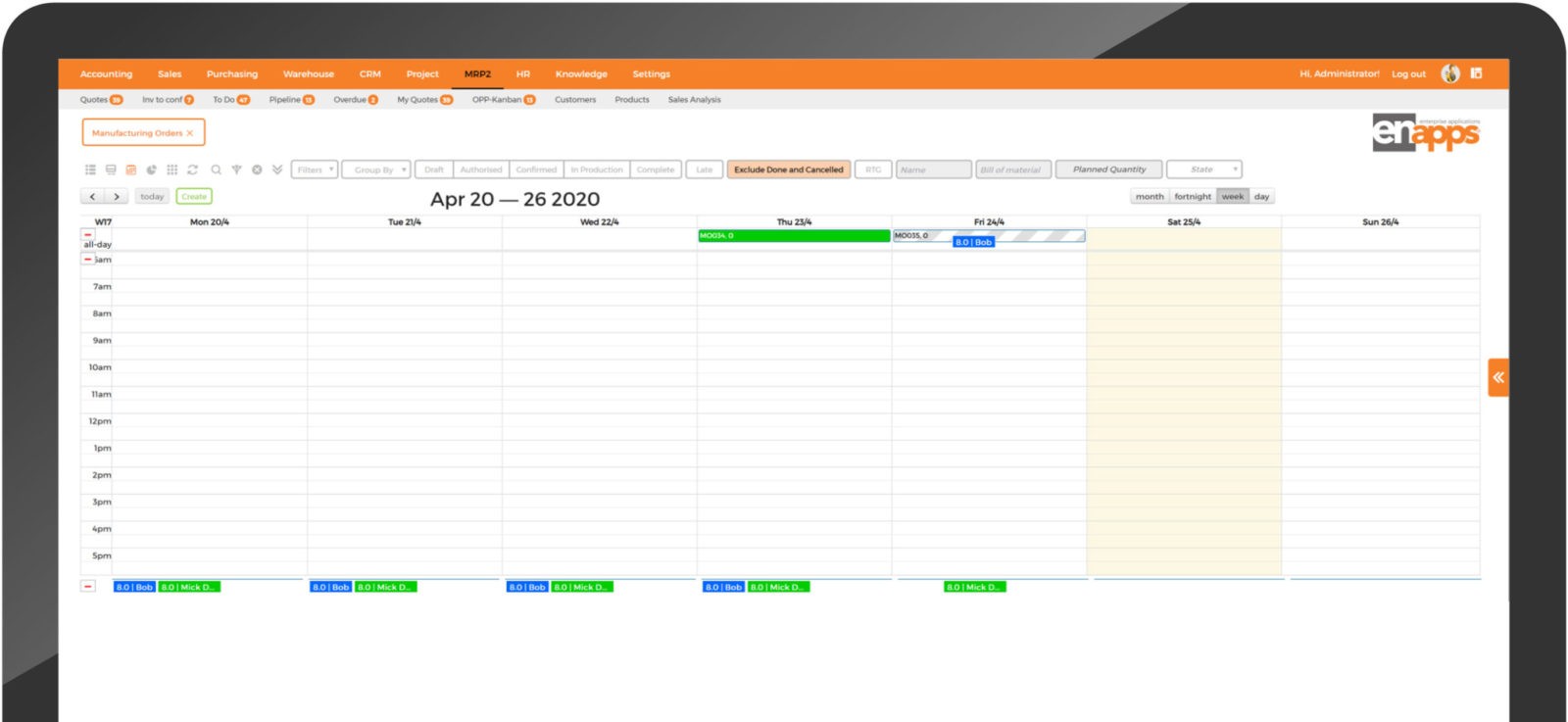

Enapps ERP Manufacturing Orders can be viewed and scheduled in both the calendar and Kanban views. If schedule or stock conflicts do become a problem, moving a Manufacturing Order in the plan is simple via dragging the appropriate item on the screen. Available Resources can also be matched to Manufacturing Orders to ensure production capacity is fully optimised.

By capturing the labour and machine time taken for each Manufacturing Order, Enapps ERP provides the process to accurately record and track the actual cost of production of your manufactured products.

Capture the start and stop times for specific jobs, so productivity can be calculated.

Drag and drop resources such as machines and people to the appropriate tasks.

Effectively manage sales and stock demand by fully utilising the system BOMs.

This is standard within our system, all components and finished goods are fully traceable.

Complex BOM makeup is supported as standard and this includes BOMs with formulas.

When a manufacturing process needs to be completed in a certain order along with other criteria.

Book an Enapps demonstration!

Complete our enquiry form and we'll get back to you to arrange your free demonstration either on-site or in our London office